CANDOUR TECHTEX LIMITED

(Formerly known as CHANDNI TEXTILES ENGINEERING INDUSTRIES LTD.)

Chandni Textiles Engineering Industries Ltd, incorporated on 17-6-1986, has its manufacturing facilities in Ankleshwar Gujarat for 1.2 million meters of light velvet fabrics mainly for the domestic market for ladies and gents apparel and light home furnishings. The company also set up a plastic division at Gonde, Nashik in 2020 for production of plastic moulded components like vegetable and fruit crates, invertor battery casings and parts for travel bags and for automotive parts with a capacity of 4500 tons per annum.

The name of the company was changed to Candour Techtecx Limited with effect from 4-2-2022 keeping in line with the starting of the new Technical Textiles Project. The company has set up a new Coating + Lamination project for manufacture of various types of Technical Textiles in Technical Collaboration with a British Company.

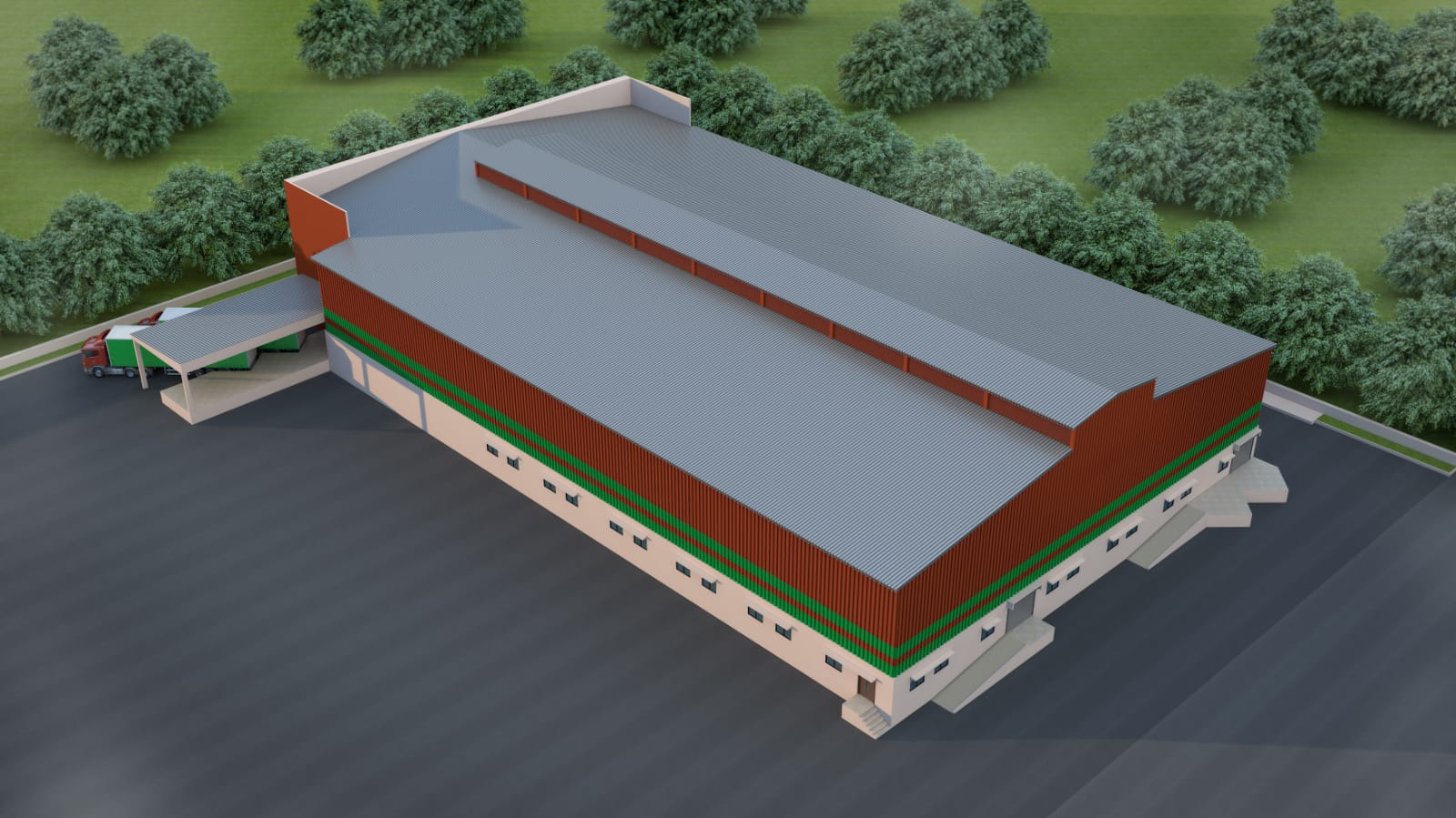

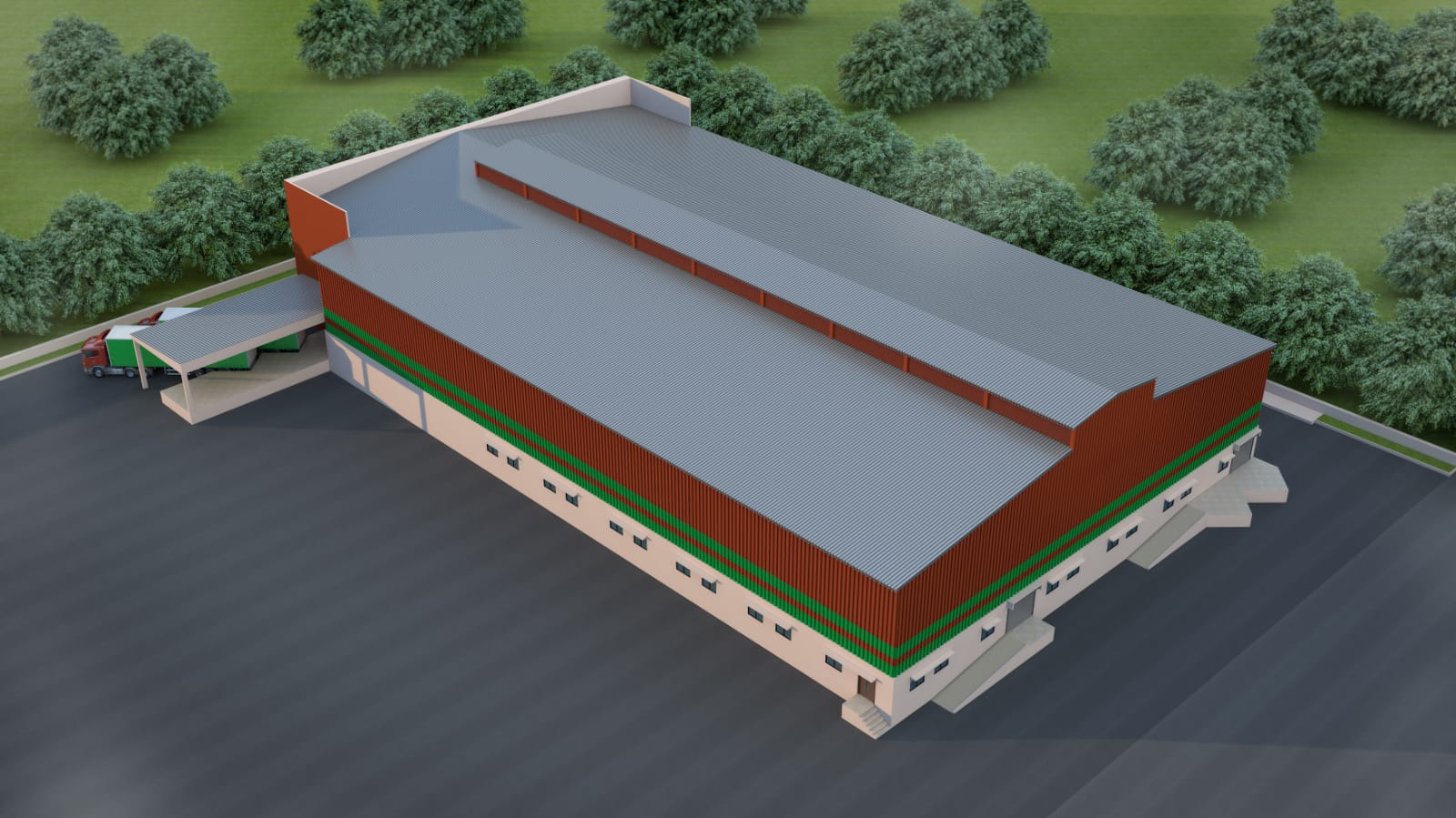

The company has acquired Industrial Land admeasuring 22,681 sq mtr in Plot No. C-6 at Malegaon (Ajang Ravalgaon) and has constructed industrial building of approximately 55,000 square foot wherein they will install 2 lines of 2.2 m and a 3.5 m Coating and flocking unit and a 2.4 m Hot Melting Lamination Line in the first phase and subsequently add further 2 coating lines of the same capacity dedicated for exports

Complete technical knowhow will be supplied by the British Company, who is in the field of Coating and Lamination since the last 25 years. They have supplied their technology to various Technical Textile manufacturing units in different countries of the world. They will not only supply the crucial Coating and Flocking unit along with the Hot Melt Lamination line but also provide full knowhow for the next 5 years for producing different types of Technical Textiles. They along with their local representative will oversee the installation and the trial production and also guide from time to time for successful manufacture of different products. They would also assist in the export of our Technical Textiles to different countries in Europe and USA especially for the defence sector.

The proposed plant is expected to start production by April 2023 and will have a initial capacity to manufacture : 24 Lac meters per annum of coated fabrics 55 Lac meters per annum of laminated fabrics

A technical textile is a special type of material or product designed for specific purposes, and offers unique and exclusive characteristics and properties that are far different from those of normal fabrics. Technical textile products exhibit enhanced performance over traditional textiles.

Technical textile products are manufactured using natural as well as manmade fibres such as Nomex, Kevlar, Spandex, Twaron, Glass and Carbon etc. These fibres exhibit enhanced functional properties like higher tenacity, excellent insulation, improved thermal resistance and chemical resistance etc.

Hence, these high performance fibres find place in varied industries and applications that comprise a wide range of products with diverse properties used in defence sector, home furnishing, automobiles, healthcare, sports, civil engineering, agriculture, shipping, industrial safety, personal protection and other consumer goods with specific purposes. Based on usage, there are 12 technical textile segments. They are classified as follows:

• Agrotech - Shade nets, crop covers, fishing nets, etc.

• Buildtech - Scaffolding nets, awnings, canopies, wall coverings, etc.

• Clothtech - Coated laces, interlinings, zip fasteners, labels, etc.

• Geotech - Geo-grids, gabions, geo-bags, etc.

• Hometech- Fibre fill, blinds fabrics, mosquito nets, furniture fabrics, etc.

• Indutech - Conveyor belts, bolting cloth, coated abrasives, composites, etc.

• Meditech - Diapers, wipes surgical sutures, hernia mesh, artificial ligaments, etc.

• Mobiltech - Tyre cord, seat belt webbing, airbag, insulation felts, seat covers, etc.

• Oekotech - Geo-membranes, geo-synthetic clay liners, etc.

• Packtech - Leno bags, soft luggage, jute hessian and sacks, shopping bags, etc.

• Protech - Bullet proof jackets, fire retardant apparel, chemical protective clothing,

etc.

• Sportech - Sport composites, artificial turfs, parachute fabrics, sleeping bags, etc.

The future of the textile industry in India has a positive outlook and is mirrored by increasingly strong consumption rates in the domestic market as well as the growing demand for exports. Moreover, the industry has earned a unique place in the economy due to its strong future outlook, numerous employment opportunities it has generated and the strong export numbers it has generated.

The company has an advantage over export of the coated and laminated products to various countries in the world Various import substitute products made from coating and lamination and which are in high demand are as under :

Defence Sector

Military- Nuclear, Chemical & Biological Protection Suits. Suits for tenting, gun covers, rucksacks, ammunition pouches, ponchos,camouflage for personnel, Electronic EMF Shielding And Protective Tents etc.

Military Textiles

• Covers for the protection of military equipment against weather, photography, etc.

• Camouflage

• Groundsheets

• Sleeping bags

• Tarpaulins

• Tents

Blackout lining and curtain fabrics

Flame Retardant furnishing fabrics

Back coated fabrics

Thermally lined curtains

Vertical blinds, panel curtains

Baggage fabrics

Bed protector, jacketing materials, studio materials

Fire Retardant:- Fabrics and Uniforms

Water Proof: - Garments and Fabrics

Work Wear: - Foul Weather Protective Clothing

- Electrical Utility

- Gas utility

- Water and sewerage utilities

- Building industry

- Coal mining industry

- Construction industry

- Army

- Navy

- Air force

- Airport personnel

- Petrol pump attendants/forecourt attendants

- Lollipop personnel

- Traffic wardens

- Police

- Fire brigades

- Airline staff

- Ambulance (including high visibility clothing)

Medical and Hygiene Products

There are many applications for coating and laminating in the medical and hygiene field.

Surgical Dressings

Are coated with adhesives.

Surgeons Gowns etc.

Parts are coated to confer protection to the wearer against the passage of blood and

bacteria. Increasingly the surgeons gown and hospital drapes market is being met by the use

of water vapour permeable but liquid and virus impermeable fabric laminates, which although

expensive at initial purchase stage, can be re-sterilized many times, making the cost per

utilization lower than that of disposable products, and the performance guarantee higher.

Biocidal Wipes

Are produced by utilising micro-encapsulated sterilants onto a substrate.

Plaster of Paris

It is a coating on a fabric substrate

Bags & Sacks

Industrial bags and sacks used in many industrial applications, and by the Post Office, will

usually be coated fabrics.Bulk storage bags, in which an increasing quantity of bulk dry raw

materials (cement, sugar, grain, fertilizers, etc.) is transported, are made from coated

fabrics.

Banner Fabrics

The majority of banner fabrics are coated in order to improve the durability, stability and

to minimise fray.

Fire Safety- Fire Retardant Fabrics for Mandaps andSocial Gathering

Air Bags-For elders, for protecting them from hip bone fractures.

Motor Bike Air Bags